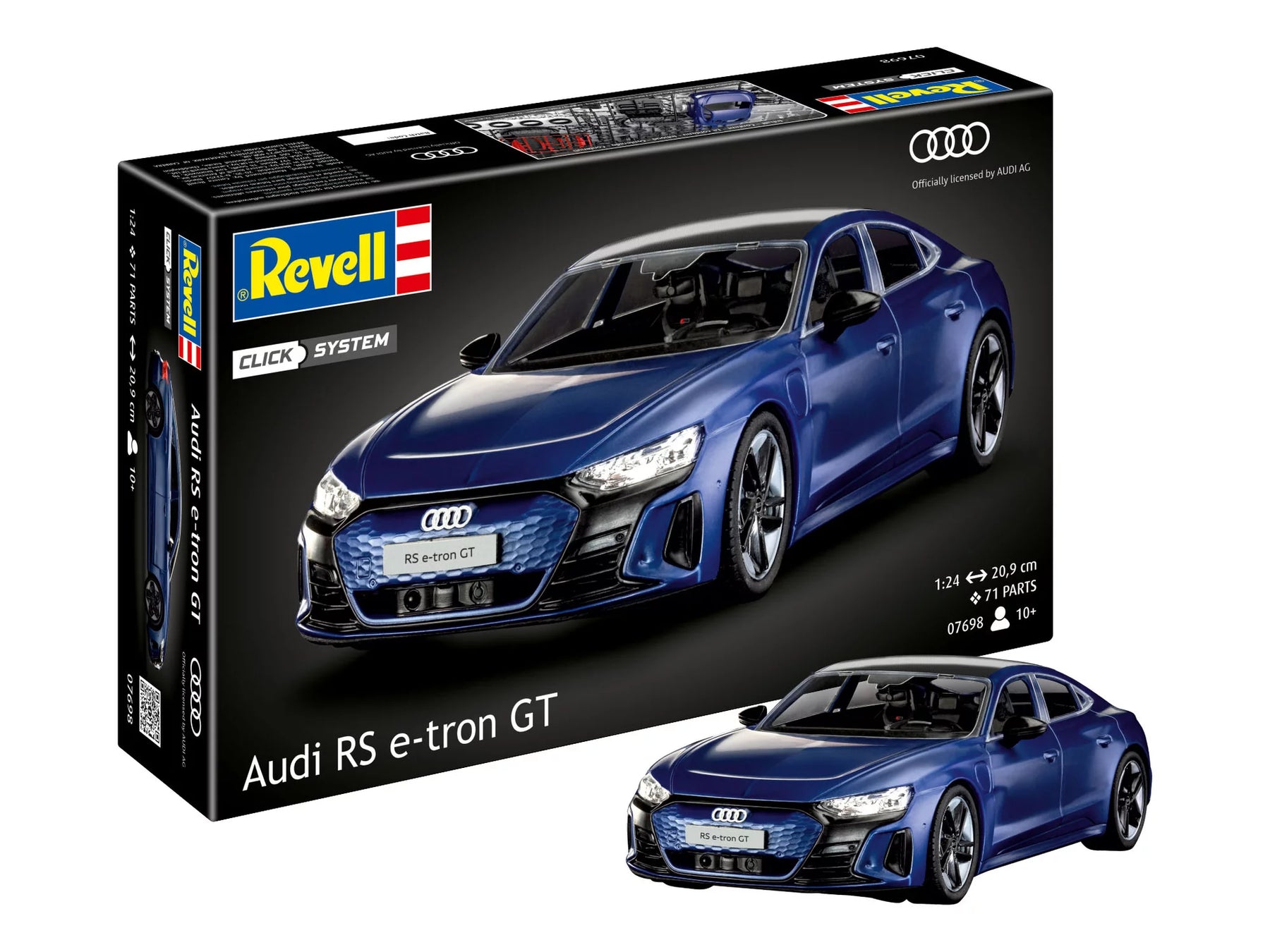

Next generation model building

What makes the click system so special?

The click system is based on a sophisticated plug-in principle in which the components are connected to one another using precisely manufactured connecting elements. This technology completely eliminates the need for glue and ensures a significantly cleaner operation. The connections are designed in such a way that they offer a firm hold and at the same time can be detached again if necessary.

Advantages for every model builder

The adhesive-free construction has several key advantages. On the one hand, drying times are eliminated, which significantly speeds up the construction process. On the other hand, your fingers stay clean because no sticky residue can form. Beginners in particular appreciate the system's tolerance for errors - incorrectly positioned parts can be easily removed and placed correctly.

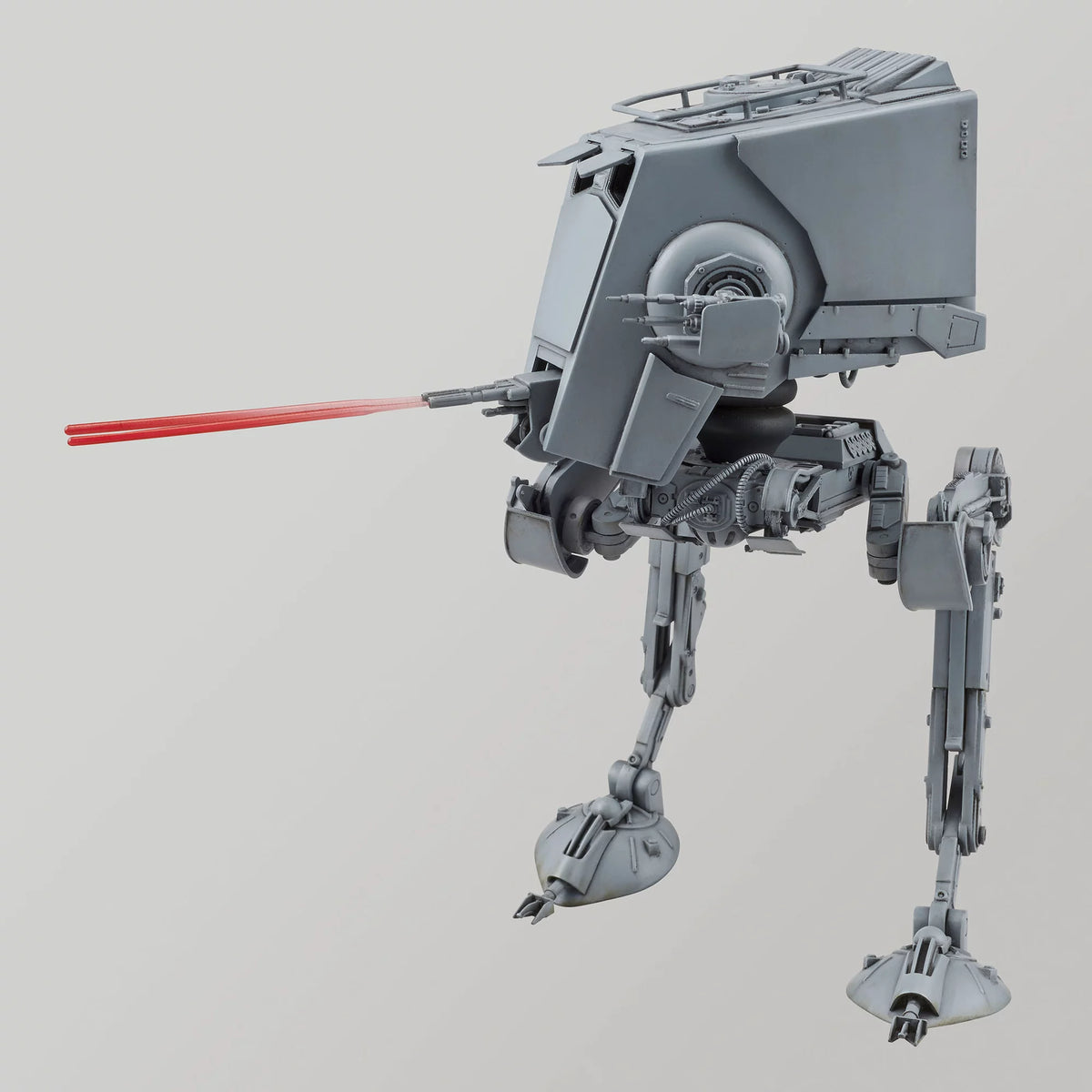

Precision meets user-friendliness

The components of the click system are manufactured with the highest precision to ensure optimal fit. Each part fits into the overall structure with millimeter precision, creating professional results. The colored injection moldings are already pre-colored, which makes additional painting work optional and further reduces the time required.

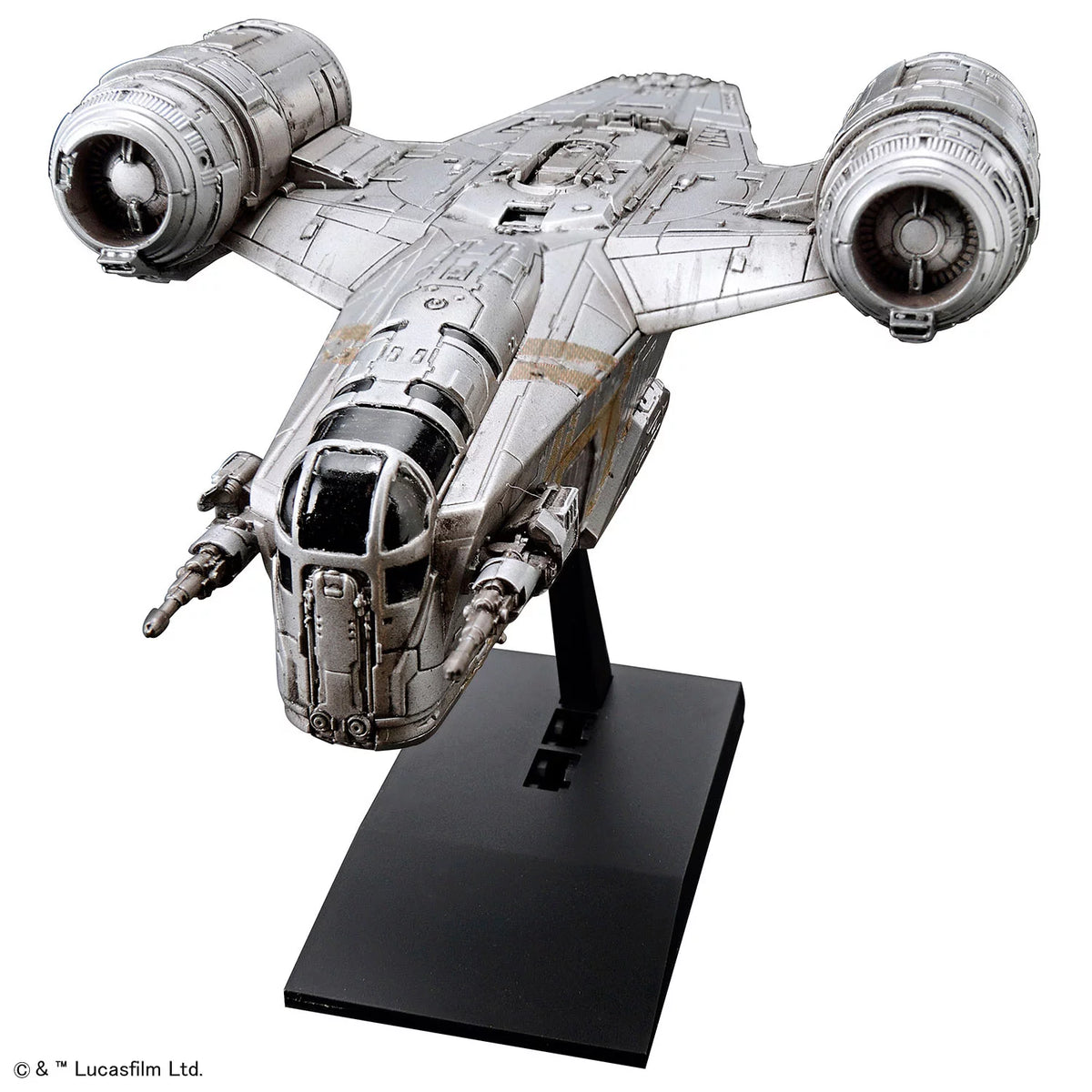

Quality and attention to detail

Despite the simplified design, there is no need to compromise on the level of detail. The models impress with the finest details and authentic proportions. The robust construction ensures that the finished models remain stable and retain their shape even when handled frequently.