The right equipment for every model maker

Why professional model building tools make the difference

Good tools are the foundation of successful model building projects. You decide on precise cuts, clean splices and professional surface treatment. Model making tools differ significantly from conventional DIY tools in their precision, handiness and special properties for fine materials such as plastic, resin or etched parts.

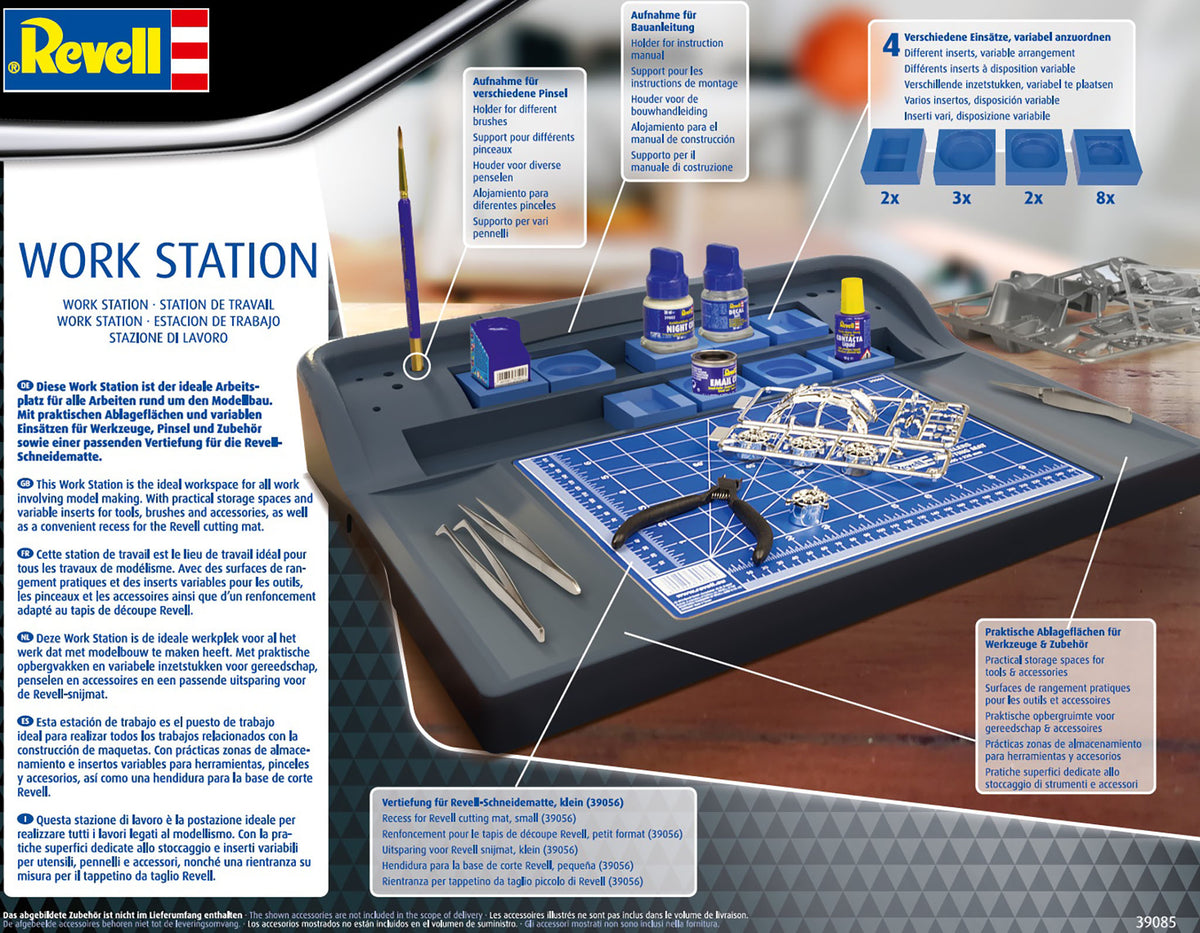

Basic equipment for model building

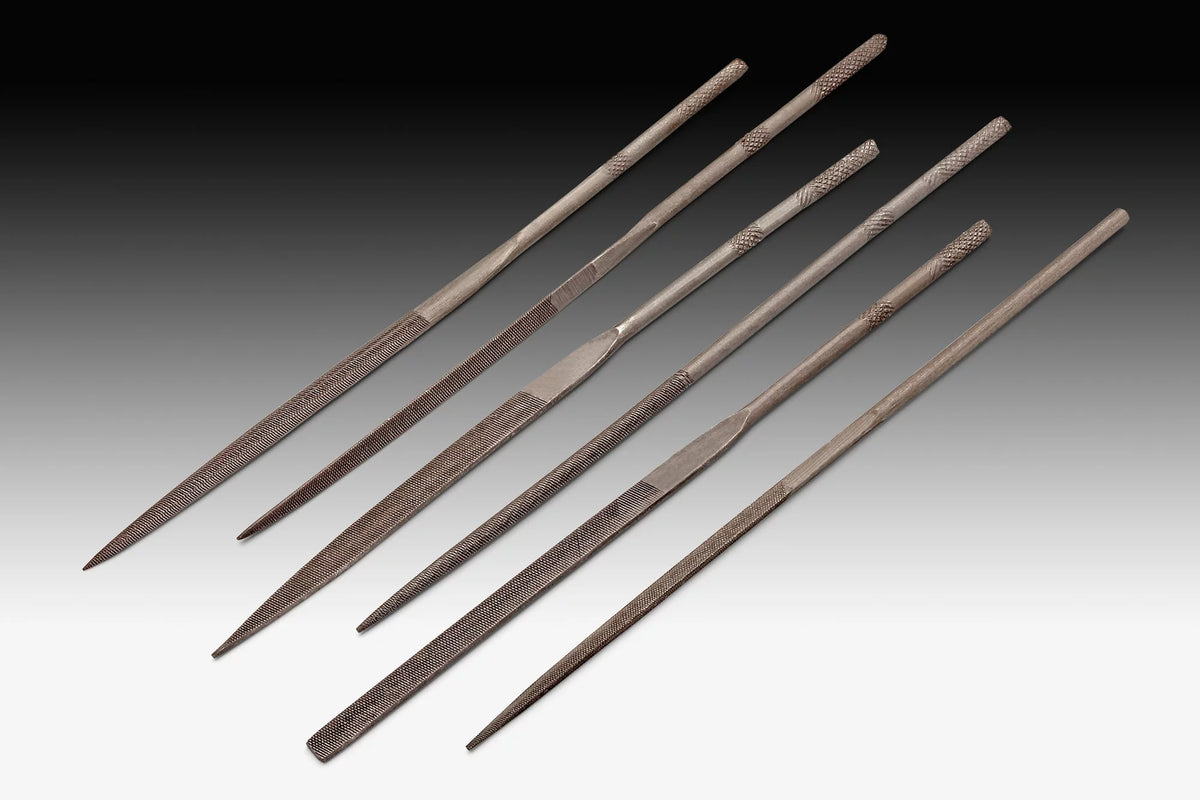

The most important tools form the heart of every model making workshop. Diagonal cutters precisely separate components from the molded parts without leaving any pressure marks or damage. Model making knives with interchangeable blades enable clean cuts and fine detailed work. Files in different grain sizes smooth cut edges and precisely shape components. Scrapers remove excess glue or material with millimeter precision.

Specialized tools for advanced users

Experienced model makers rely on specialized tools for demanding tasks. Precision tweezers handle the smallest etched parts safely. Clamps hold components in place during gluing and ensure exact alignment. Scribing tools create realistic panel lines. Miniature size drill bits create perfect holes for antennas or details.

Care and quality pay off

High-quality tools will last for years if cared for properly. Regular cleaning prevents glue residue, sharp blades guarantee precise cuts. Investing in quality tools pays off with better results and longer durability. Cheap alternatives often frustrate with imprecise work or rapid wear and tear.

The right tool selection depends on your preferred model types and your experience. It's best for beginners to start with a basic set that contains the most important tools. Advanced students supplement their equipment with special tools for their preferred techniques and materials.