Why 3D cardboard model making is the perfect choice for model building enthusiasts

Understand the special features of cardboard model making

3D cardboard model making is fundamentally different from traditional plastic model making and offers unique advantages. The specially developed model cardboard is characterized by its high stability and precise punching quality. The prefabricated components can be removed from the sheets without additional tools or adhesives and connected to each other using clever plug-in systems.

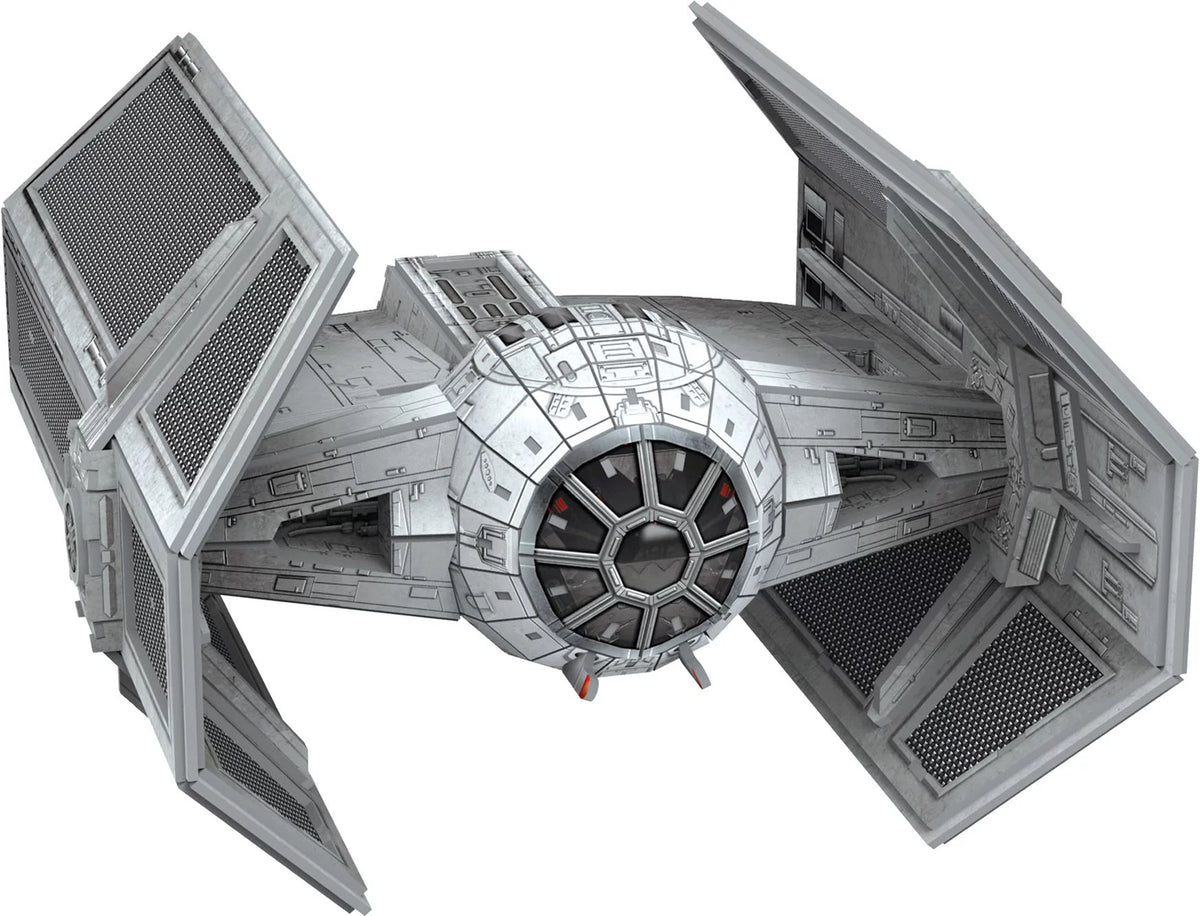

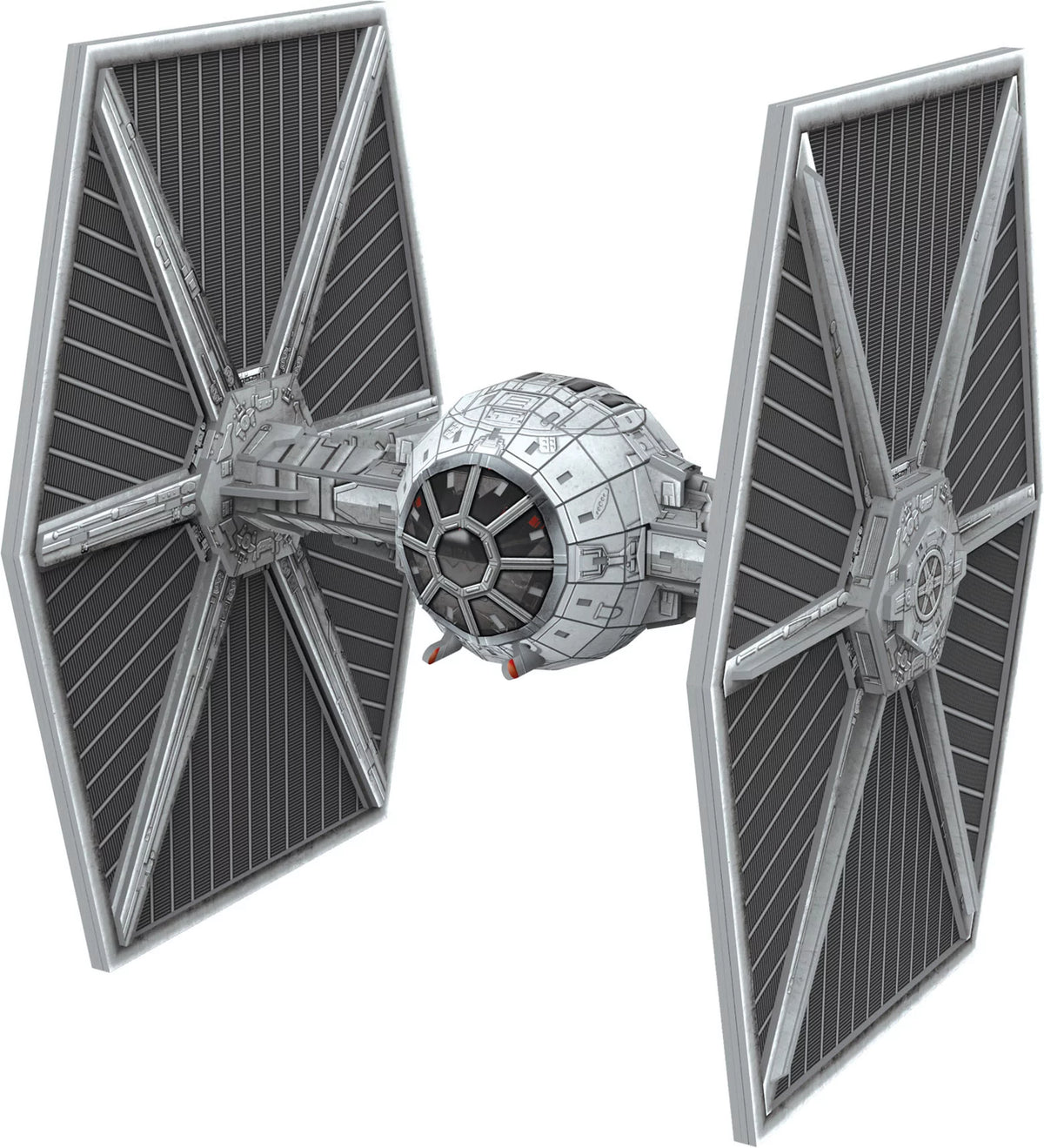

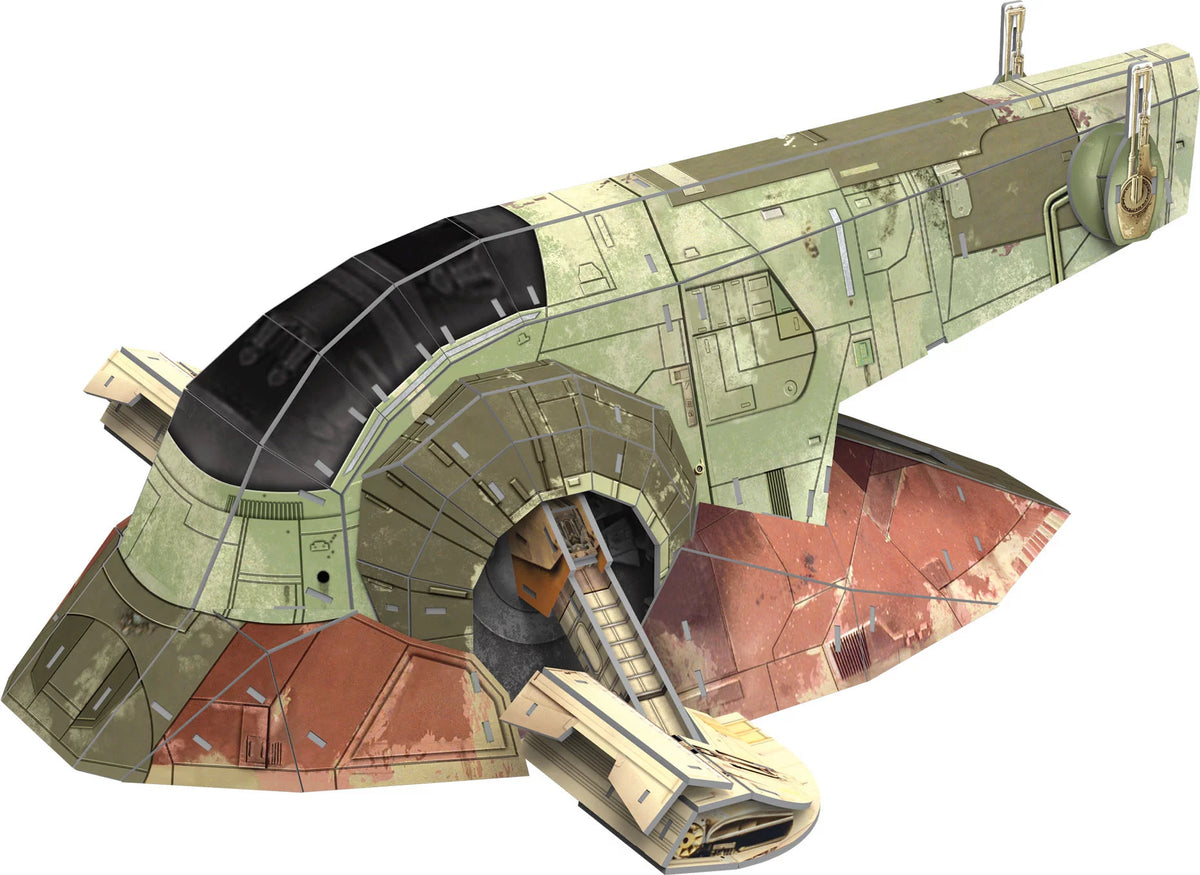

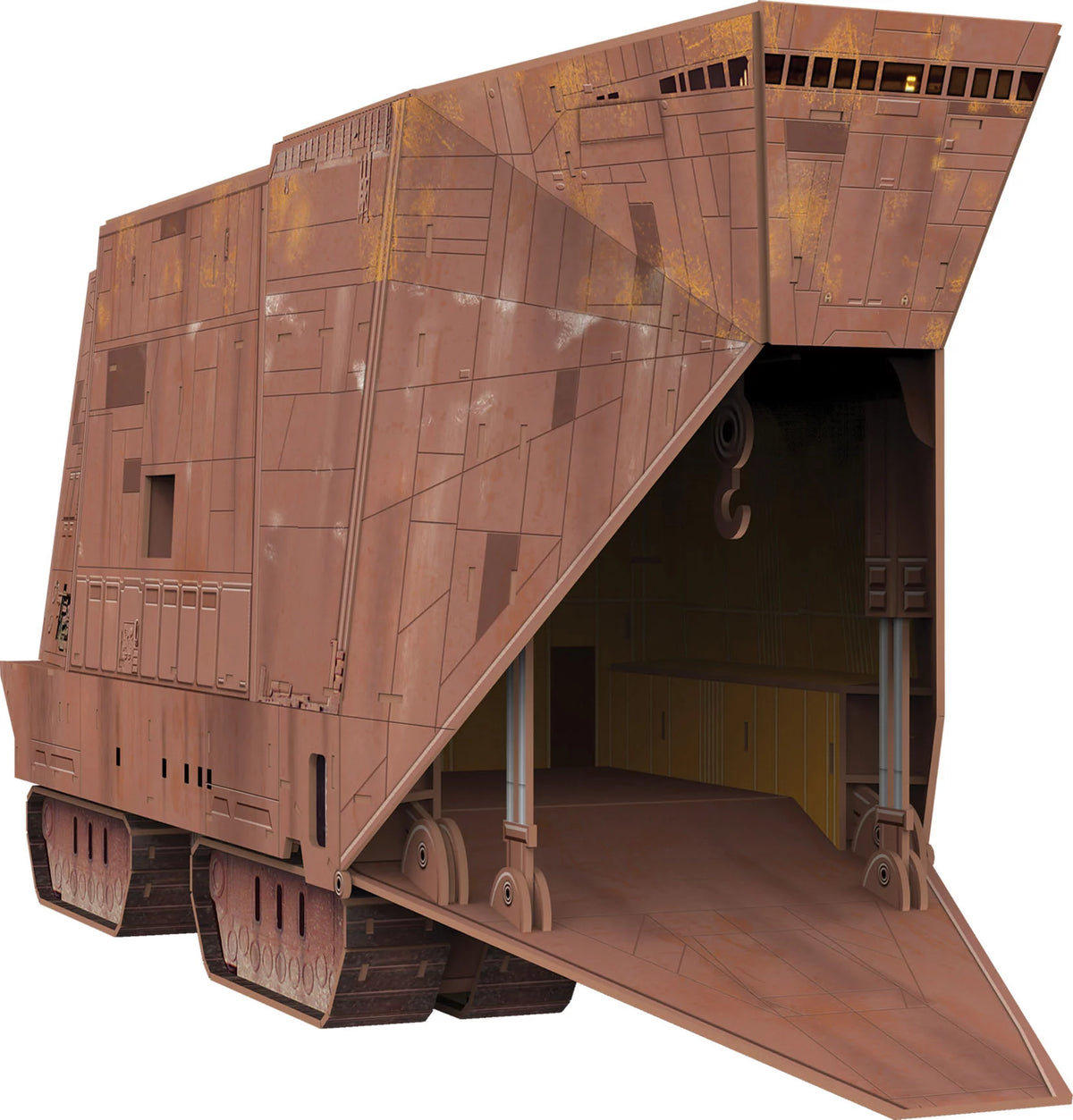

The surface design takes place during the printing process, creating realistic textures and colors. This technology makes it possible to faithfully display complex details such as rivets and welds, wood grain or metallic surfaces.

Which models are suitable for cardboard model making?

The spectrum ranges from historical vehicles to architectural models to science fiction objects. Vehicle models from different eras that impress with their authentic attention to detail are particularly popular. Building models allow you to recreate famous buildings and create impressive dioramas.

For beginners, models with fewer parts and larger components are recommended. Advanced model makers can try their hand at more complex designs with delicate details. The difficulty levels are clearly marked and make it easier to select suitable projects.

Advantages over other model building materials

Cardboard models score points for their environmental friendliness and easy handling. The material is 100 percent recyclable and does not require any harmful solvents or adhesives. The processing is carried out using standard household tools such as cutters and rulers.

The cost efficiency makes this branch of model making particularly attractive. High-quality cardboard models cost significantly less than comparable plastic kits and still offer impressive levels of detail. In addition, there is no need for post-processing by sanding, priming or painting.