Professional airbrush spare parts for permanently precise painting work

Why quality replacement parts are crucial

Airbrush systems are precision instruments whose performance depends largely on the quality of their individual components. Wear parts such as nozzles, needles and seals are subject to natural wear and tear with regular use and directly influence the spray quality. High-quality replacement parts not only ensure even paint distribution, but also significantly extend the life of your entire airbrush equipment.

The most important spare parts at a glance

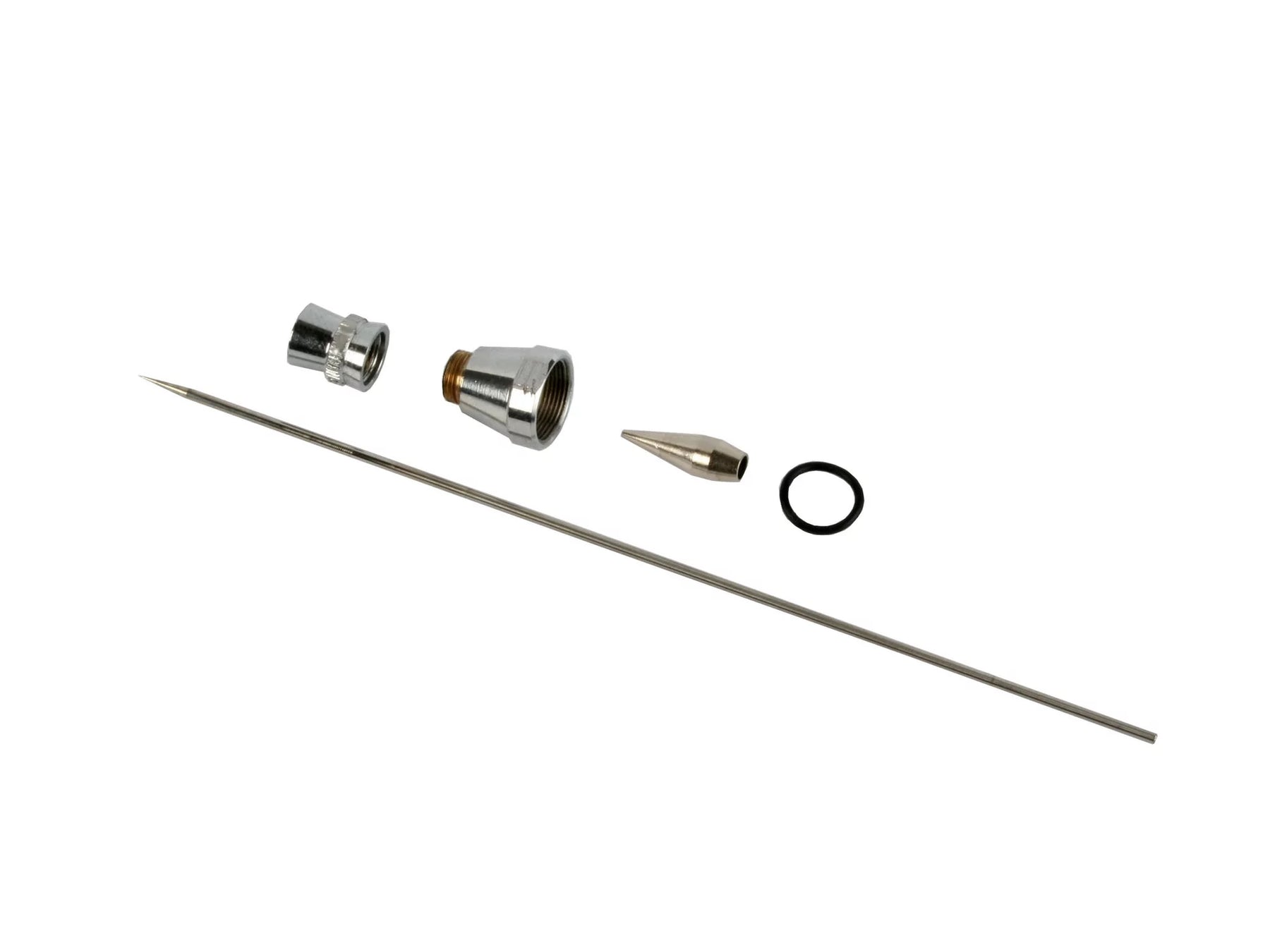

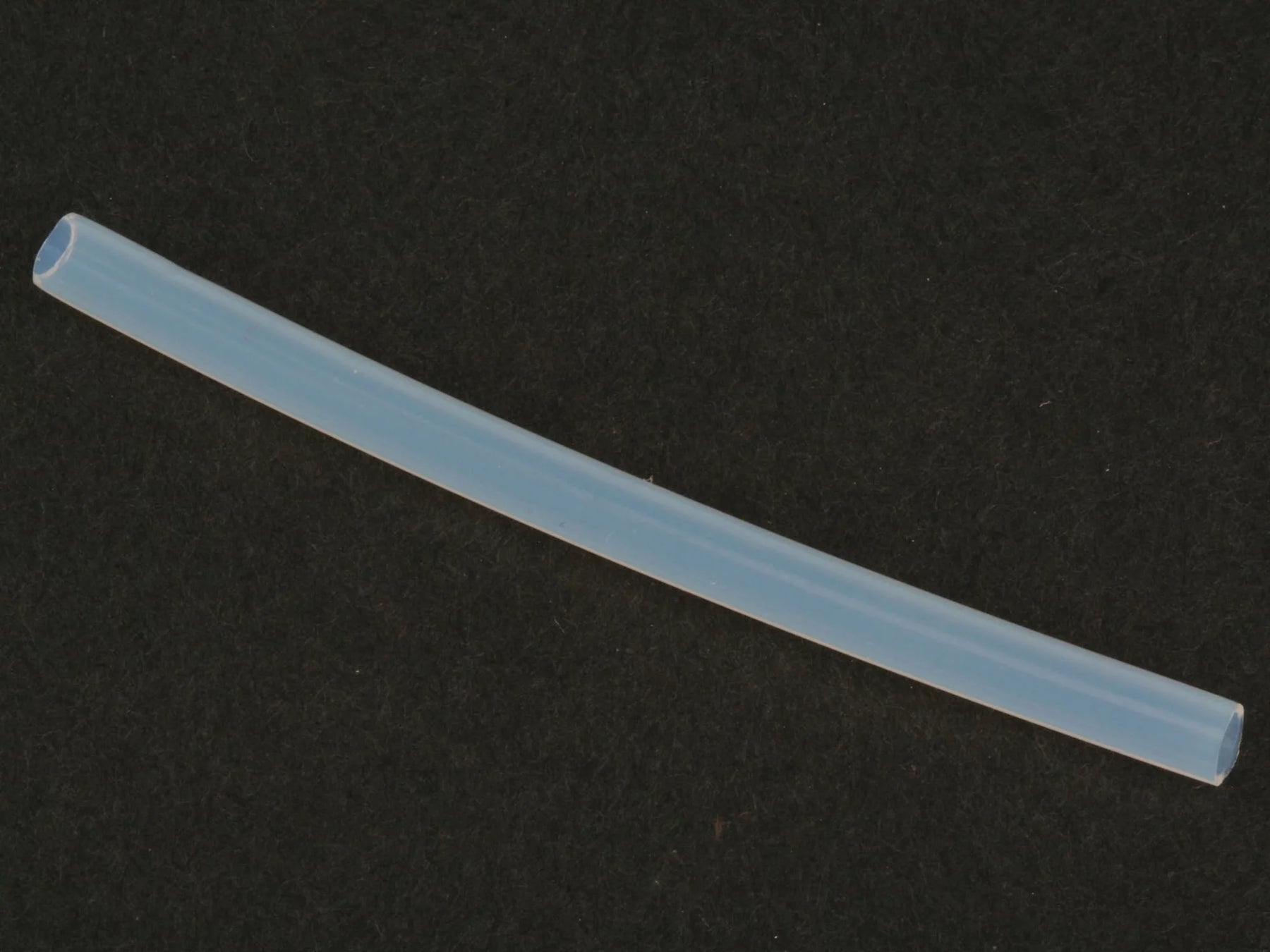

nozzles and needles form the heart of every airbrush. You determine the line width and precision of the color application. Different nozzle sizes enable different applications - from fine detailed work to large-area primers. Seals and O-rings provide the necessary seal between moving parts and prevent air leaks that would lead to uneven spray patterns.

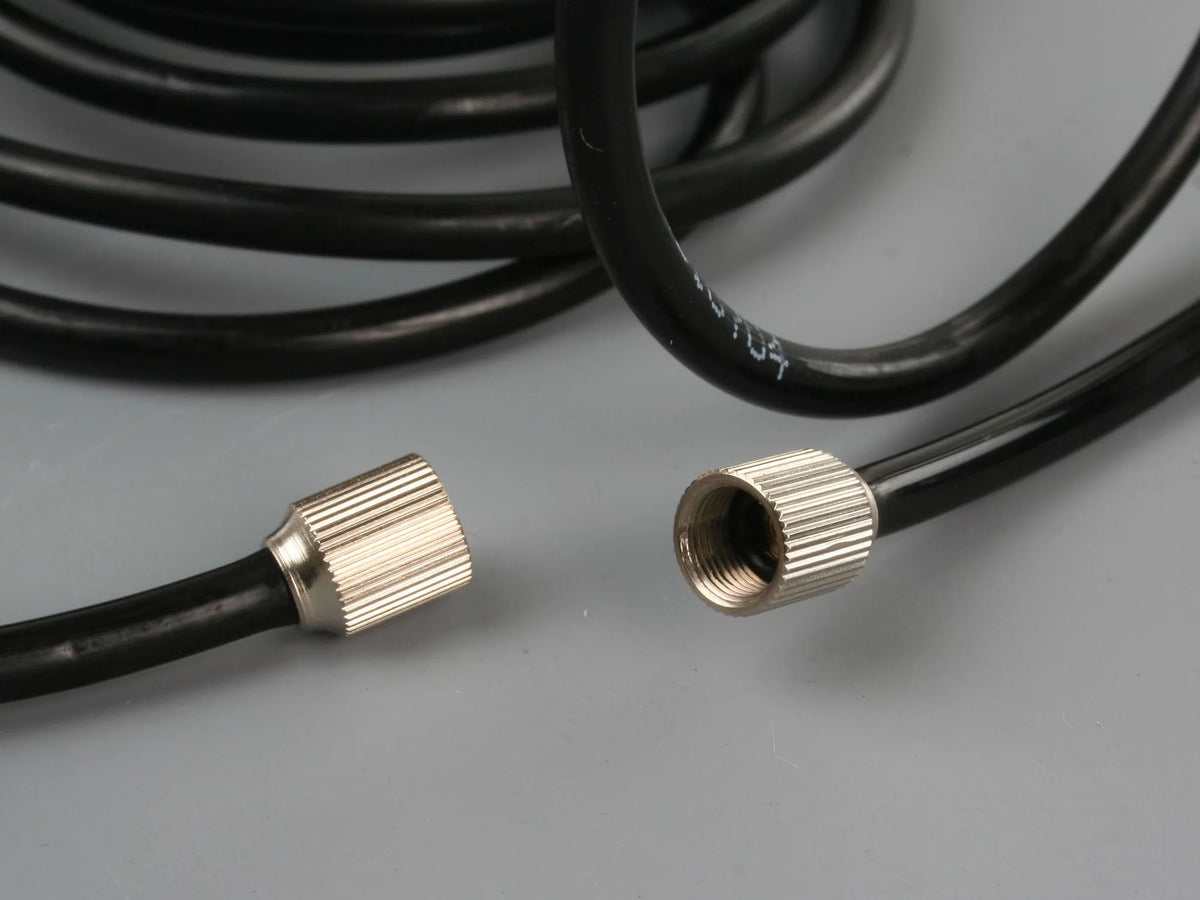

Paint cups and adapters expand the flexibility of your airbrush system. Depending on the project, different cup sizes can increase work efficiency. Trigger mechanisms and springs ensure precise control of the paint flow and air supply.

When should spare parts be replaced?

Regular maintenance is crucial for consistent results. Nozzles should be replaced if there is visible damage or an uneven spray pattern. Replace seals if air or paint escapes uncontrollably. Needles need replacement if they are bent or worn at the tip. A well-maintained airbrush with high-quality spare parts delivers professional painting results for years and saves costs in the long term by avoiding incorrect spraying and material waste.