The right equipment for perfect airbrush work

Why a good compressor is crucial

A reliable airbrush compressor is the heart of every airbrush equipment. Without consistent air pressure and continuous air supply, uneven color gradients, splashes or broken lines result. Quality compressors ensure constant pressure between 1.5 and 4 bar and enable precise control over paint application and spray pattern.

Compressor types for different applications

Piston compressors work with a compressed air tank and offer constant air pressure even during longer work phases. They are particularly suitable for extensive projects and detailed work as the tank compensates for pressure fluctuations.

Diaphragm and piston compressors without tank are more compact and cheaper, but provide continuous airflow without intermediate storage. This variant is completely sufficient for smaller models and occasional airbrush work.

Important purchasing criteria

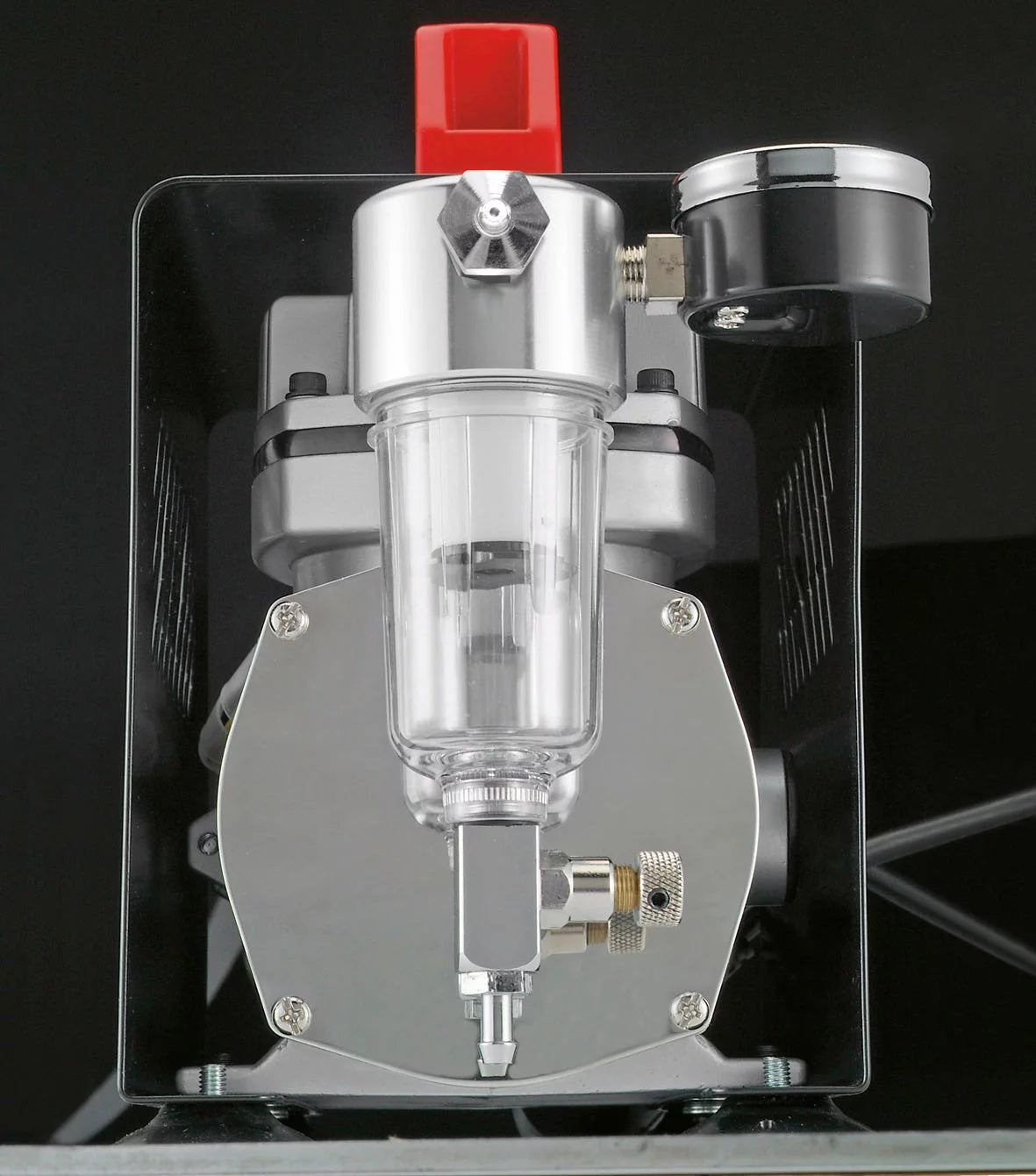

Volume plays an important role, especially in living rooms. Modern compressors operate almost silently at less than 50 dB. Automatic shut-off functions protect the motor and power consumption, while adjustable pressure regulators enable different spraying techniques.

An integrated water separator prevents condensation from forming in the air line - important for even color distribution without disruption. Carrying handles and compact design make transport between workstations easier.

Care and maintenance

Regular maintenance significantly extends its lifespan. Air filters should be cleaned or replaced monthly. Condensation in the tank must be drained after each use to avoid corrosion. Oil-filled compressors require annual oil changes according to the manufacturer's instructions.